A fagen sarrafa injina na zamani, injinan hakowa da injinan niƙa CNC sune na yau da kullun kuma mahimman kayan aikin injin, waɗanda ke da bambance-bambance masu mahimmanci a cikin ayyuka, tsari, da yanayin aikace-aikacen. Domin samar muku da zurfin fahimta da cikakkiyar fahimta game da waɗannan nau'ikan kayan aikin injin guda biyu, mai kera injin milling na CNC zai ba ku cikakken bayani a ƙasa.

1. m bambanci

Halayen rigidity na injin hakowa

An kera na'urar hakowa ne don yin tsayin daka da manyan runduna a tsaye, tare da ƙananan ƙarfi na gefe. Wannan shi ne saboda babban hanyar sarrafa na'urar hakowa shine hakowa, kuma ɗigon rawar ya fi yin rawar jiki a tsaye yayin aiki, kuma ƙarfin da ake amfani da shi a kan aikin ya fi ta'allaka ne a cikin axial direction. Sabili da haka, an ƙarfafa tsarin na'urar hakowa a tsaye a tsaye don tabbatar da kwanciyar hankali, rage girgizawa da karkatar da hankali yayin aikin hakowa.

Koyaya, saboda raunin injunan hakowa don jure wa sojojin gefe, wannan kuma yana iyakance aikace-aikacen su a wasu yanayi mai rikitarwa. Lokacin da ya zama dole don aiwatar da mashin ɗin gefe akan kayan aikin ko kuma lokacin da akwai tsangwama ta gefe yayin aikin hakowa, injin hakowa bazai iya tabbatar da daidaiton injina da kwanciyar hankali ba.

Abubuwan buƙatu masu ƙarfi don injin niƙa CNC

Ba kamar injunan hakowa ba, injinan niƙa na CNC suna buƙatar tsauri mai kyau saboda ƙarfin da aka haifar yayin aikin niƙa ya fi rikitarwa. Ƙarfin milling ba kawai ya haɗa da manyan rundunonin tsaye ba, har ma yana buƙatar yin tsayayya da manyan runduna ta gefe. A lokacin aikin niƙa, yankin lamba tsakanin mai yankan niƙa da kayan aikin yana da girma, kuma kayan aikin yana juyawa yayin yankewa tare da madaidaiciyar hanya, yana haifar da sojojin milling suna aiki a cikin kwatance da yawa.

Domin jure wa irin waɗannan rikitattun yanayi na damuwa, tsarin ƙirar injinan niƙa na CNC yawanci ya fi ƙarfi da kwanciyar hankali. Mahimman abubuwan da ke cikin kayan aikin injin, kamar gado, ginshiƙai, da ginshiƙan jagora, an yi su ne da kayan aiki masu ƙarfi da ingantattun sifofi don haɓaka ƙaƙƙarfan juriya gabaɗaya da aikin juriya. Kyakkyawan tsattsauran ra'ayi yana ba da injunan milling na CNC don kula da ingantattun mashin ɗin yayin jure wa manyan rundunonin yankan, sa su dace da sarrafa nau'ikan hadaddun sifofi da madaidaicin sassa.

2.Bambance-bambancen tsarin

Halayen tsarin injin hakowa

Tsarin na'urar hakowa yana da sauƙi, kuma a mafi yawan lokuta, idan dai an sami abinci a tsaye, zai iya biyan bukatun sarrafawa. Na'urar hakowa yawanci tana ƙunshi jikin gado, ginshiƙi, akwatin sandal, benci, da injin ciyarwa.

Gado shine ainihin abin da ke cikin injin hakowa, ana amfani da shi don tallafawa da shigar da wasu abubuwan. An kafa ginshiƙi akan gado don ba da tallafi ga babban akwatin axle. Akwatin sandal ɗin yana sanye da igiya da madaidaicin injin gudu, wanda ake amfani da shi don motsa jujjuyawar ɗigon. Ana amfani da benci na aiki don sanya kayan aiki kuma ana iya daidaita su cikin sauƙi da matsayi. Tsarin ciyarwa yana da alhakin sarrafa motsin ciyarwar axial na rawar rawar jiki don cimma zurfin kula da hakowa.

Saboda tsarin sarrafa injinan hakowa mai sauƙi, tsarin su yana da sauƙi kuma farashin su yana da ɗan ƙaramin ƙarfi. Amma wannan tsari mai sauƙi kuma yana iyakance ayyuka da kewayon sarrafa injin hakowa.

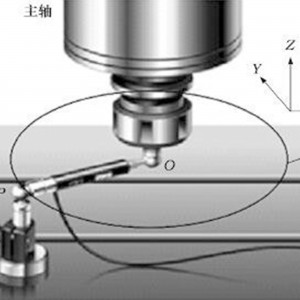

A tsarin abun da ke ciki na CNC milling inji

Tsarin injunan niƙa na CNC ya fi rikitarwa. Ba wai kawai yana buƙatar cimma abinci a tsaye ba, amma mafi mahimmanci, yana kuma buƙatar samun ayyukan ciyarwa a kwance a kwance. CNC milling inji yawanci hada da sassa kamar gado, shafi, worktable, sirdi, spindle akwatin, CNC tsarin, feed drive tsarin, da dai sauransu.

Gado da ginshiƙi suna ba da ingantaccen tsarin tallafi don kayan aikin injin. Wurin aiki zai iya motsawa a kwance don cimma ciyarwar gefe. An shigar da sirdi a kan ginshiƙi kuma yana iya fitar da akwatin sandal don motsawa a tsaye, yana samun abinci mai tsayi. Akwatin sandal ɗin sanye take da ingantattun kayan aiki da ingantattun na'urorin watsa saurin sauri don biyan buƙatun dabarun sarrafawa daban-daban.

Tsarin CNC shine babban sashin kulawa na injin milling na CNC, wanda ke da alhakin karɓar umarnin shirye-shirye da canza su zuwa siginar sarrafa motsi don kowane axis na kayan aikin injin, cimma daidaitattun ayyukan injin. Tsarin tuƙi na ciyarwa yana jujjuya umarnin tsarin CNC zuwa ainihin motsi na kayan aiki da sirdi ta hanyar abubuwan da aka haɗa kamar injina da sukurori, yana tabbatar da daidaiton machining da ingancin saman.

3.Processing aiki

Ƙarfin sarrafawa na injin hakowa

Na'urar hakowa galibi na'ura ce da ke amfani da ɗigon bulo don haƙa da sarrafa kayan aiki. A karkashin yanayi na al'ada, jujjuyawar ƙwanƙwasa shine babban motsi, yayin da motsi na axial na injin hakowa shine motsin ciyarwa. Injin hakowa na iya yin ta cikin rami, rami makafi da sauran ayyukan injina akan kayan aikin, kuma suna iya biyan buƙatun buɗaɗɗe daban-daban da daidaitattun buƙatun ta hanyar maye gurbin diamita daban-daban da nau'ikan.

Bugu da kari, na'urar hakowa tana iya yin wasu ayyuka masu saukin hakowa da tapping. Koyaya, saboda ƙayyadaddun tsarin sa da na aiki, injinan hakowa ba su iya yin hadaddun mashin ɗin a saman kayan aikin, kamar filaye mai lebur, tsagi, gears, da sauransu.

Kewayon injina na injin niƙa CNC

Injin niƙa na CNC suna da fa'idar iya aiki da yawa. Yana iya amfani da masu yankan niƙa don aiwatar da lebur ɗin kayan aiki, da kuma hadaddun sifofi kamar tsagi da gears. Bugu da kari, CNC milling inji kuma iya sarrafa workpieces tare da hadaddun profiles, kamar lankwasa saman da kuma maras lokaci saman, ta amfani da musamman yankan kayan aikin da shirye-shirye hanyoyin.

Idan aka kwatanta da na'urorin hakowa, CNC milling inji suna da mafi girma machining yadda ya dace, sauri sauri, kuma zai iya cimma mafi girma machining daidaito da kuma surface ingancin. Wannan ya sanya injinan niƙa na CNC da yawa ana amfani da su a fannoni kamar masana'antar ƙira, sararin samaniya, da abubuwan kera motoci.

4. Kayan aiki da kayan aiki

Kayan aiki da kayan aiki don injin hakowa

Babban kayan aikin da ake amfani da shi a cikin injin hakowa shine ƙwanƙwasa, kuma ana zaɓar sifa da girman ɗigon buƙatun bisa ga bukatun sarrafawa. A cikin aikin hakowa, ana amfani da na'urori masu sauƙi irin su pliers, V-blocks, da dai sauransu don matsayi da kuma matsa kayan aiki. Saboda gaskiyar cewa ƙarfin da na'urar hakowa ke sarrafawa ya fi mayar da hankali a cikin jagorancin axial, ƙirar ƙirar yana da sauƙi mai sauƙi, musamman tabbatar da cewa aikin ba zai motsa ko juya ba yayin aikin hakowa.

Kayan aiki da kayan aiki don injin niƙa na CNC

Akwai nau'ikan kayan aikin yankan iri-iri da ake amfani da su a cikin injinan niƙa na CNC, waɗanda suka haɗa da injin ƙarshen ƙwallon ƙwallon ƙafa, injin ƙarewa, injin fuska, da sauransu ban da masu yankan niƙa gama gari. Daban-daban na kayan aikin yankan sun dace da dabarun sarrafawa daban-daban da buƙatun sifa. A cikin milling na CNC, abubuwan da ake buƙata don ƙirar kayan aiki sun fi girma, kuma abubuwan da suka haɗa da rarraba ƙarfi, daidaiton matsayi na aikin aiki, da girman ƙarfin ƙwanƙwasa yana buƙatar la'akari don tabbatar da cewa aikin ba ya fuskantar ƙaura da nakasar yayin aikin injin.

Don inganta aikin injiniya da daidaito, injinan milling na CNC yawanci suna amfani da na'urori na musamman da kayan aiki, irin su kayan haɗin gwiwa, na'urorin lantarki, da sauransu.

5. Shirye-shirye da Ayyuka

Shirye-shirye da aiki na injin hakowa

Shirye-shiryen na'urar hakowa abu ne mai sauƙi, yawanci kawai yana buƙatar saitin sigogi kamar zurfin hakowa, saurin gudu, da ƙimar ciyarwa. Masu aiki za su iya kammala aikin injiniya ta hanyar yin aiki da hannu ko maɓallin kayan aikin injin, kuma suna iya amfani da tsarin CNC mai sauƙi don tsarawa da sarrafawa.

Saboda ingantacciyar fasahar sarrafa kayan aikin hakowa, aikin yana da sauƙin sauƙi, kuma buƙatun fasaha don masu aiki ba su da ƙarancin ƙarfi. Amma wannan kuma yana iyakance aikace-aikacen injin hakowa a cikin hadaddun sarrafa sashi.

Shirye-shirye da kuma aiki na CNC milling inji

Shirye-shiryen na'urorin milling na CNC sun fi rikitarwa, suna buƙatar amfani da ƙwararrun software na shirye-shirye irin su MasterCAM, UG, da dai sauransu, don samar da shirye-shiryen machining dangane da zane-zane da bukatun kayan aiki na sassa. A yayin aiwatar da shirye-shirye, abubuwa da yawa kamar hanyar kayan aiki, yanke sigogi, da jerin tsari suna buƙatar la’akari da su don tabbatar da daidaiton mashin ɗin da inganci.

Dangane da aiki, injinan niƙa na CNC galibi ana sanye su da allon taɓawa ko bangarorin aiki. Masu aiki suna buƙatar sanin tsarin aiki da ayyuka na tsarin CNC, su sami damar shigar da umarni da sigogi daidai, da kuma lura da matsayi yayin aikin injin. Saboda hadaddun fasahar sarrafa injinan CNC, akwai babban buƙatu don matakin fasaha da ilimin ƙwararrun masu aiki, wanda ke buƙatar horo na musamman da aiki don ƙwarewa sosai.

6. Filin aikace-aikace

Yanayin aikace-aikacen na'urorin hakowa

Saboda tsarinsa mai sauƙi, ƙarancin farashi, da aiki mai dacewa, ana amfani da injin hakowa sosai a cikin wasu ƙananan wuraren sarrafa kayan aikin injiniya, wuraren kulawa, da gidaje masu sarrafa kansu. An fi amfani dashi don sarrafa sassa tare da sassa masu sauƙi da ƙananan buƙatu, kamar nau'in nau'in rami, sassan haɗin kai, da dai sauransu.

A wasu masana'antun da ake samarwa da yawa, ana kuma iya amfani da na'urorin hakowa don sarrafa sassa masu sauƙi, kamar ramukan hakowa akan karafa. Koyaya, don madaidaicin madaidaici da hadaddun sassa masu siffa, injunan hakowa ba za su iya biyan buƙatun ba.

Iyakar aikace-aikace na CNC milling inji

CNC milling inji an yadu amfani a filayen kamar mold masana'antu, aerospace, mota gyara, lantarki kayan aiki, da dai sauransu saboda su abũbuwan amfãni daga high machining daidaito, high dace, da kuma iko ayyuka. Ana iya amfani da shi don aiwatar da nau'i-nau'i masu rikitarwa daban-daban, daidaitattun sassa, sassan akwatin, da dai sauransu, kuma yana iya saduwa da bukatun masana'antu na zamani don ingantaccen aiki da ingantaccen aiki.

Musamman ma a wasu manyan masana'antun masana'antu, injinan niƙa na CNC sun zama kayan aiki masu mahimmanci, suna taka muhimmiyar rawa wajen haɓaka ingancin samfur, rage zagayowar samarwa, da rage farashi.

7. Kwatanta misalan inji

Don ƙarin fahimtar bambance-bambance a cikin tasirin injina tsakanin injunan hakowa da injunan milling na CNC, za a kwatanta takamaiman misalan inji guda biyu a ƙasa.

Misali 1: Kera sashin farantin karfe mai sauƙi

Gudanar da injin hakowa: Da farko, gyara kayan aikin a kan benci na aiki, zaɓi bit ɗin da ya dace, daidaita zurfin hakowa da ƙimar abinci, sannan fara injin hakowa don sarrafa hakowa. Saboda gaskiyar cewa injunan hakowa na iya yin aikin hakowa a tsaye kawai, buƙatun don daidaiton matsayi na rami da ingancin saman ba su da girma, kuma ingancin sarrafawa yana da ƙasa kaɗan.

CNC milling inji sarrafa: Lokacin amfani da CNC milling inji don aiki, mataki na farko shi ne yin samfurin sassa a cikin 3D da kuma samar da machining shirin bisa ga machining tsari bukatun. Sa'an nan shigar da workpiece a kan kwazo kayan aiki, shigar da machining shirin ta hanyar CNC tsarin, da kuma fara inji kayan aiki na inji. CNC milling inji iya cimma lokaci guda machining na mahara ramuka ta hanyar shirye-shirye, da kuma iya tabbatar da matsayi daidaito da kuma surface ingancin ramukan, ƙwarai inganta machining yadda ya dace.

Misali na 2: Sarrafa hadadden sashi

sarrafa injin hakowa: Don irin waɗannan sassa masu siffa masu rikiɗa, injinan hakowa ba su iya kammala ayyukan sarrafawa. Ko da an sarrafa ta ta wasu hanyoyi na musamman, yana da wahala a tabbatar da daidaiton mashin ɗin da ingancin saman.

CNC milling inji sarrafa: Ta amfani da iko ayyuka na CNC milling inji, yana yiwuwa a farko yi m machining a kan mold sassa, cire mafi yawan wuce haddi, sa'an nan kuma yi Semi daidai da daidaici machining, kyakkyawan samun high-madaidaici da high quality-mold sassa. A lokacin aikin mashin ɗin, ana iya amfani da nau'ikan kayan aiki daban-daban kuma ana iya haɓaka sigogin yanke don haɓaka haɓakar mashin ɗin da ingancin saman.

Ta hanyar kwatanta misalai guda biyu da ke sama, za a iya ganin cewa injinan hakowa sun dace da wasu sassaƙaƙan sarrafa ramuka, yayin da injinan niƙa na CNC ke da ikon sarrafa sifofi daban-daban masu sarƙaƙƙiya da sassa masu tsayi.

8. Takaitaccen bayani

A taƙaice, akwai bambance-bambance masu mahimmanci tsakanin injin hakowa da na'urorin milling na CNC dangane da tsauri, tsari, ayyukan sarrafawa, kayan aikin kayan aiki, ayyukan shirye-shirye, da filayen aikace-aikace. Na'ura mai hakowa yana da tsari mai sauƙi da ƙananan farashi, kuma ya dace da sauƙi mai sauƙi da aikin haɓaka ramuka; CNC milling inji suna da halaye na high madaidaici, high dace, da kuma multifunctionality, wanda zai iya saduwa da bukatun zamani masana'antu domin hadaddun sassa aiki.

A cikin ainihin samarwa, injunan hakowa ko injin injin CNC ya kamata a zaɓi su da kyau bisa ƙayyadaddun ayyukan sarrafawa da buƙatun don cimma sakamako mafi kyawun aiki da fa'idodin tattalin arziki. A lokaci guda, tare da ci gaba da ci gaban fasaha da ci gaban masana'antun masana'antu, injinan hakowa da na'urorin niƙa na CNC suma suna ci gaba da ingantawa da kammalawa, suna ba da goyon bayan fasaha mai ƙarfi don haɓaka masana'antar sarrafa injina.