Tsarin CNC na kayan aikin injin CNC ya haɗa da na'urorin CNC, tukin ciyarwa (naúrar sarrafa saurin ciyarwa da motar servo), tuƙi (nau'in sarrafa saurin juzu'i da injin spindle) da abubuwan ganowa. Ya kamata a haɗa abubuwan da ke sama lokacin zabar tsarin sarrafa lambobi. 1. Zaɓin na'urar CNC (1) Zaɓin Nau'in Zaɓi Zaɓi na'urar CNC mai dacewa bisa ga nau'in kayan aikin CNC. Gabaɗaya magana, na'urar CNC tana da nau'ikan sarrafawa waɗanda suka dace da mota, hakowa, gundura, niƙa, niƙa, tambari, yankan tartsatsin wutar lantarki, da sauransu, kuma yakamata a zaɓa ta hanyar da aka yi niyya. (2) Zaɓin aikin na'urorin sarrafa lambobi daban-daban ya bambanta sosai. Adadin gatura mai sarrafa shigarwa shine guda-axis, 2-axis, 3-axis, 4-axis, 5-axis, ko ma fiye da gatura 10, fiye da gatura 20; Adadin gatura na haɗin gwiwa shine 2 ko fiye da gatura 3, kuma matsakaicin saurin ciyarwa shine 10m/min, 15m/min, 24m/mi N,240m/min; ƙuduri shine 0.01mm, 0.001mm, 0.0001mm. Waɗannan alamomin sun bambanta, kuma farashin kuma ya bambanta. Ya kamata ya dogara ne akan ainihin bukatun kayan aikin injin. Misali, 2-axis ko 4-axis (mai riƙe kayan aiki biyu) an zaɓi sarrafawa don sarrafa juzu'i na gabaɗaya, kuma an zaɓi haɗin haɗin axis fiye da 3 don sarrafa sassan jirgin. Kada ku bi sabon matakin mafi girma, ya kamata ku yi zaɓi mai ma'ana.

(3) Zaɓin aiki Tsarin CNC na kayan aikin injin CNC yana da ayyuka da yawa, ciki har da ayyuka na asali - ayyuka masu mahimmanci na na'urorin CNC; ayyuka na zaɓi – ayyuka don masu amfani don zaɓar. Wasu daga cikin ayyukan an zaɓi su ne don magance abubuwa daban-daban na sarrafawa, wasu don haɓaka ingancin sarrafawa, wasu don sauƙaƙe shirye-shirye, wasu kuma don haɓaka aiki da aikin kulawa. Wasu ayyukan zaɓin sun dace, kuma dole ne ka zaɓi wani don zaɓar wannan. Sabili da haka, ya zama dole don zaɓar bisa ga buƙatun ƙira na kayan aikin injin, kada kuyi nazari, zaɓi aikin a cikin matakai da yawa, kuma ku watsar da ayyukan da suka dace, don rage aikin na'urar na'urar CNC kuma haifar da asarar da ba dole ba. Akwai nau'ikan masu sarrafa shirye-shirye guda biyu a cikin aikin zaɓin: ginannen ciki da masu zaman kansu. Zai fi dacewa don zaɓar ƙirar da aka gina, wanda ke da nau'i daban-daban. Da farko, ya kamata a zaba bisa ga adadin shigarwa da siginar fitarwa tsakanin na'urar CNC da kayan aikin injin. Makiyoyin da aka zaɓa ya kamata su kasance daɗaɗɗen maki masu amfani, kuma kofi na iya ƙarawa da canza buƙatar aikin sarrafawa. Abu na biyu, yana da mahimmanci don kimanta ma'auni na shirin da aka tsara kuma zaɓi ƙarfin ajiya. Ma'auni na shirin yana ƙaruwa tare da rikitarwa na kayan aikin injin, kuma ƙarfin ajiya yana ƙaruwa. Ya kamata a zaɓe shi bisa ga takamaiman yanayi. Hakanan akwai lokacin sarrafawa, aikin koyarwa, mai ƙidayar ƙidayar lokaci, ƙidayawa, gudun ba da sanda na ciki da sauran ƙayyadaddun fasaha, kuma adadin ya kamata ya dace da buƙatun ƙira.

(3) Zaɓin aiki Tsarin CNC na kayan aikin injin CNC yana da ayyuka da yawa, ciki har da ayyuka na asali - ayyuka masu mahimmanci na na'urorin CNC; ayyuka na zaɓi – ayyuka don masu amfani don zaɓar. Wasu daga cikin ayyukan an zaɓi su ne don magance abubuwa daban-daban na sarrafawa, wasu don haɓaka ingancin sarrafawa, wasu don sauƙaƙe shirye-shirye, wasu kuma don haɓaka aiki da aikin kulawa. Wasu ayyukan zaɓin sun dace, kuma dole ne ka zaɓi wani don zaɓar wannan. Sabili da haka, ya zama dole don zaɓar bisa ga buƙatun ƙira na kayan aikin injin, kada kuyi nazari, zaɓi aikin a cikin matakai da yawa, kuma ku watsar da ayyukan da suka dace, don rage aikin na'urar na'urar CNC kuma haifar da asarar da ba dole ba. Akwai nau'ikan masu sarrafa shirye-shirye guda biyu a cikin aikin zaɓin: ginannen ciki da masu zaman kansu. Zai fi dacewa don zaɓar ƙirar da aka gina, wanda ke da nau'i daban-daban. Da farko, ya kamata a zaba bisa ga adadin shigarwa da siginar fitarwa tsakanin na'urar CNC da kayan aikin injin. Makiyoyin da aka zaɓa ya kamata su kasance daɗaɗɗen maki masu amfani, kuma kofi na iya ƙarawa da canza buƙatar aikin sarrafawa. Abu na biyu, yana da mahimmanci don kimanta ma'auni na shirin da aka tsara kuma zaɓi ƙarfin ajiya. Ma'auni na shirin yana ƙaruwa tare da rikitarwa na kayan aikin injin, kuma ƙarfin ajiya yana ƙaruwa. Ya kamata a zaɓe shi bisa ga takamaiman yanayi. Hakanan akwai lokacin sarrafawa, aikin koyarwa, mai ƙidayar ƙidayar lokaci, ƙidayawa, gudun ba da sanda na ciki da sauran ƙayyadaddun fasaha, kuma adadin ya kamata ya dace da buƙatun ƙira.

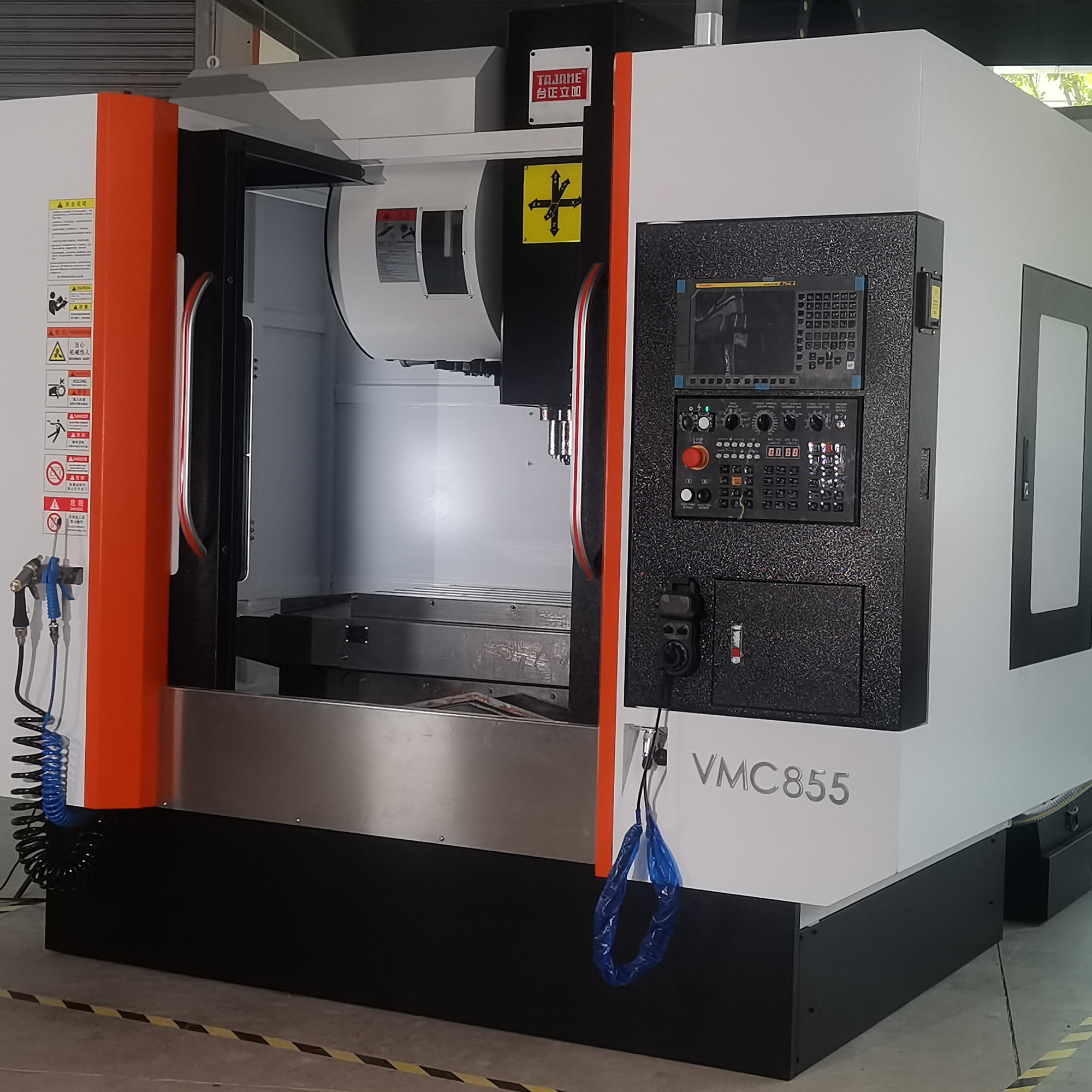

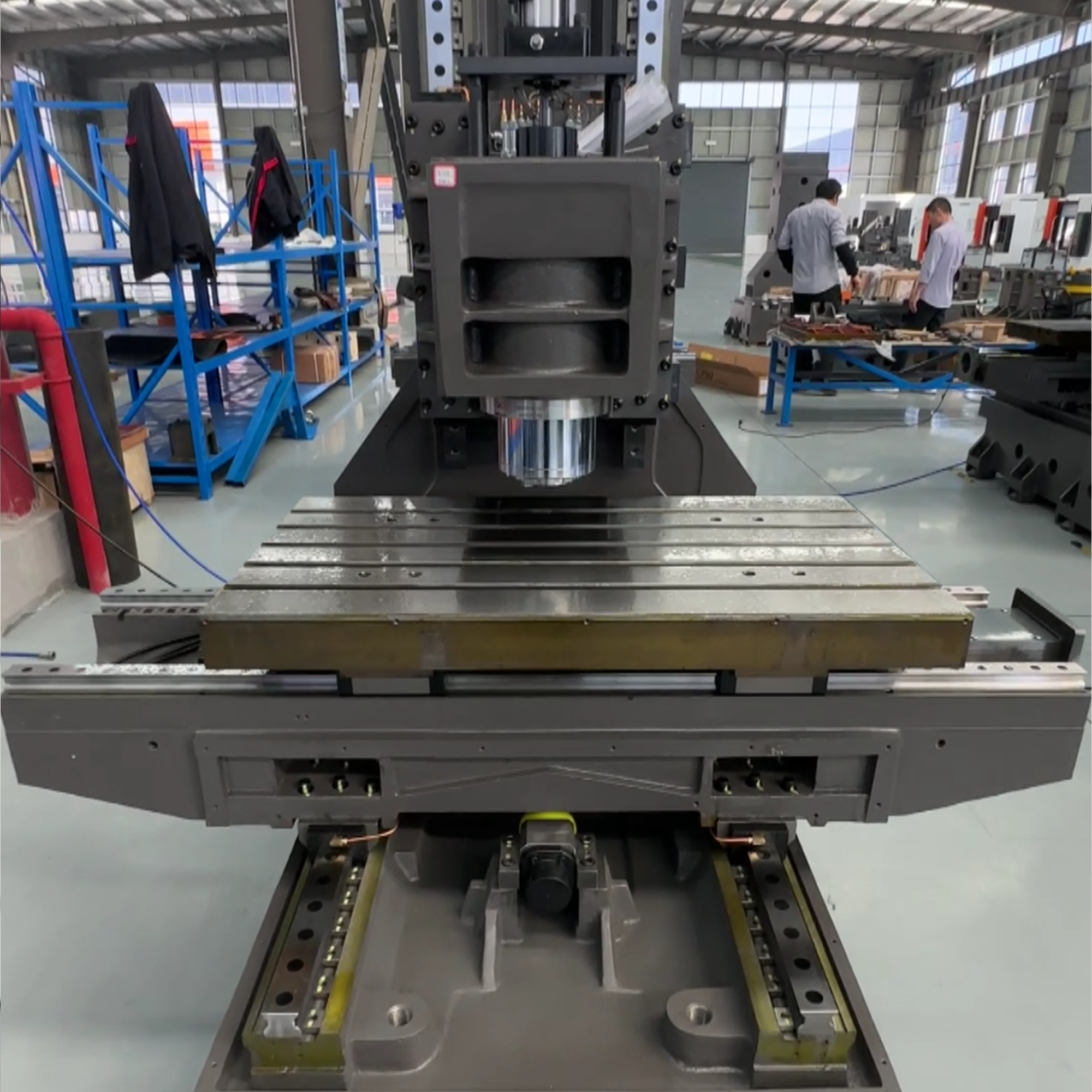

( 4) Farashin Xu Ze a kasashe daban-daban da kuma masana'antun na'urorin CNC suna samar da samfurori daban-daban na samfurori tare da babban bambanci a farashin. Dangane da gamsar da nau'in sarrafawa, aikin aiki da zaɓin aiki, yakamata mu bincika ƙimar ƙimar aiki da zaɓin na'urorin CNC tare da ƙimar ƙimar ƙimar girma don rage farashin. Shin akwai sashen sabis na fasaha na musamman don samar da kayan gyara da sabis na kulawa na lokaci mai tsawo don gane fa'idodin fasaha da tattalin arziki. 2. Zaɓin firikwensin ciyarwa (1) AC servo motor ya fi dacewa, saboda idan aka kwatanta da motar DC, inertia na rotor yana da ƙananan, amsa mai mahimmanci yana da kyau, ƙarfin fitarwa yana da girma, saurin juyawa yana da girma, tsarin yana da sauƙi, farashin yana da ƙananan, kuma yanayin aikace-aikacen ba shi da iyaka. ( 2) Zaɓi motar servo na ƙayyadaddun ƙayyadaddun da suka dace ta hanyar ƙididdige ma'auni daidai da nauyin nauyin da aka kara a cikin motar motar. ( 3) Mai samar da kayan abinci yana ba da jerin samfurori na samfurori don na'urar sarrafa saurin ciyarwa da kuma motar servo, don haka bayan an zaɓi motar servo, an zaɓi naúrar sarrafa saurin gudu daga littafin samfurin. 3. Zabi na tukin tuƙi (1) Motar da ake amfani da shi na yau da kullun an fi so, saboda ba shi da hani na commutation, babban gudu da babban ƙarfin kamar DC spindle motor. Matsakaicin ka'idojin saurin wutar lantarki akai-akai yana da girma, amo yana da ƙasa, kuma farashin yana da arha. A halin yanzu, kashi 85% na kayan aikin injin CNC ana sarrafa su ta hanyar igiyoyin AC a duniya. (CNC na'ura mai aiki) (2) Zaɓi motar motsa jiki bisa ga ka'idoji masu zuwa: 1 Ana ƙididdige ikon yankewa bisa ga kayan aikin injin daban-daban, kuma motar da aka zaɓa ya kamata ya dace da wannan buƙatun; 2 Dangane da saurin hanzarin sandar da ake buƙata da lokacin raguwa, ana ƙididdige cewa ƙarfin motar kada ya wuce matsakaicin ƙarfin fitarwa na motar; 3 Lokacin da ake buƙatar sandal don farawa akai-akai da birki, dole ne a ƙididdige matakin. Matsakaicin matsakaicin wutar lantarki ba zai iya wuce ci gaba da ƙididdige ƙarfin fitarwa na motar ba; 3 ( 4) Lokacin da ake buƙatar sandal don sarrafa jagora, gwargwadon yanayin ainihin kayan aikin injin, zaɓi madaidaicin matsayi ko firikwensin maganadisu don gane ikon sarrafa sandal. 4. Zaɓin abubuwan ganowa (1) Bisa ga tsarin tsarin kula da matsayi na tsarin kula da lambobi, ƙaddamar da linzamin kwamfuta na kayan aikin injin yana auna kai tsaye ko a kaikaice, kuma an zaɓi abubuwan gano layi ko juyawa. A halin yanzu, Semi-rufe-madauki iko ana amfani da ko'ina a cikin kayan aikin injin CNC, kuma an zaɓi abubuwan ma'aunin kusurwa na juyawa (masu juyawa, masu rikodin bugun jini). (2) Dangane da buƙatun kayan aikin injin CNC don gano daidaito ko sauri, zaɓi matsayi ko abubuwan gano saurin sauri (masu samar da gwaji, masu bugun bugun jini). Gabaɗaya magana, manyan na'urorin injin sun fi dacewa da buƙatun sauri, kuma ƙayyadaddun ƙayyadaddun, ƙanana da matsakaita na kayan aikin injin sun dace da daidaito. Ƙaddamar da zaɓaɓɓen ɓangaren ganowa gabaɗaya tsari ne na girma sama da daidaiton sarrafawa. (3) A halin yanzu, mafi yawan abin da aka fi amfani da shi na gano kayan aikin injin CNC (a kwance m da injin milling) shine mai rikodin bugun jini na hoto, wanda ke zaɓar maɓallin bugun bugun jini na ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙwallon ƙwallon CNC na kayan aikin CNC, ƙaramin motsi na tsarin CNC, haɓakar umarni da haɓakar ganowa. ( 4) Lokacin zabar nau'in ganowa, yakamata a la'akari da cewa na'urar sarrafa lambobi tana da da'irar mu'amala mai dacewa.

( 4) Farashin Xu Ze a kasashe daban-daban da kuma masana'antun na'urorin CNC suna samar da samfurori daban-daban na samfurori tare da babban bambanci a farashin. Dangane da gamsar da nau'in sarrafawa, aikin aiki da zaɓin aiki, yakamata mu bincika ƙimar ƙimar aiki da zaɓin na'urorin CNC tare da ƙimar ƙimar ƙimar girma don rage farashin. Shin akwai sashen sabis na fasaha na musamman don samar da kayan gyara da sabis na kulawa na lokaci mai tsawo don gane fa'idodin fasaha da tattalin arziki. 2. Zaɓin firikwensin ciyarwa (1) AC servo motor ya fi dacewa, saboda idan aka kwatanta da motar DC, inertia na rotor yana da ƙananan, amsa mai mahimmanci yana da kyau, ƙarfin fitarwa yana da girma, saurin juyawa yana da girma, tsarin yana da sauƙi, farashin yana da ƙananan, kuma yanayin aikace-aikacen ba shi da iyaka. ( 2) Zaɓi motar servo na ƙayyadaddun ƙayyadaddun da suka dace ta hanyar ƙididdige ma'auni daidai da nauyin nauyin da aka kara a cikin motar motar. ( 3) Mai samar da kayan abinci yana ba da jerin samfurori na samfurori don na'urar sarrafa saurin ciyarwa da kuma motar servo, don haka bayan an zaɓi motar servo, an zaɓi naúrar sarrafa saurin gudu daga littafin samfurin. 3. Zabi na tukin tuƙi (1) Motar da ake amfani da shi na yau da kullun an fi so, saboda ba shi da hani na commutation, babban gudu da babban ƙarfin kamar DC spindle motor. Matsakaicin ka'idojin saurin wutar lantarki akai-akai yana da girma, amo yana da ƙasa, kuma farashin yana da arha. A halin yanzu, kashi 85% na kayan aikin injin CNC ana sarrafa su ta hanyar igiyoyin AC a duniya. (CNC na'ura mai aiki) (2) Zaɓi motar motsa jiki bisa ga ka'idoji masu zuwa: 1 Ana ƙididdige ikon yankewa bisa ga kayan aikin injin daban-daban, kuma motar da aka zaɓa ya kamata ya dace da wannan buƙatun; 2 Dangane da saurin hanzarin sandar da ake buƙata da lokacin raguwa, ana ƙididdige cewa ƙarfin motar kada ya wuce matsakaicin ƙarfin fitarwa na motar; 3 Lokacin da ake buƙatar sandal don farawa akai-akai da birki, dole ne a ƙididdige matakin. Matsakaicin matsakaicin wutar lantarki ba zai iya wuce ci gaba da ƙididdige ƙarfin fitarwa na motar ba; 3 ( 4) Lokacin da ake buƙatar sandal don sarrafa jagora, gwargwadon yanayin ainihin kayan aikin injin, zaɓi madaidaicin matsayi ko firikwensin maganadisu don gane ikon sarrafa sandal. 4. Zaɓin abubuwan ganowa (1) Bisa ga tsarin tsarin kula da matsayi na tsarin kula da lambobi, ƙaddamar da linzamin kwamfuta na kayan aikin injin yana auna kai tsaye ko a kaikaice, kuma an zaɓi abubuwan gano layi ko juyawa. A halin yanzu, Semi-rufe-madauki iko ana amfani da ko'ina a cikin kayan aikin injin CNC, kuma an zaɓi abubuwan ma'aunin kusurwa na juyawa (masu juyawa, masu rikodin bugun jini). (2) Dangane da buƙatun kayan aikin injin CNC don gano daidaito ko sauri, zaɓi matsayi ko abubuwan gano saurin sauri (masu samar da gwaji, masu bugun bugun jini). Gabaɗaya magana, manyan na'urorin injin sun fi dacewa da buƙatun sauri, kuma ƙayyadaddun ƙayyadaddun, ƙanana da matsakaita na kayan aikin injin sun dace da daidaito. Ƙaddamar da zaɓaɓɓen ɓangaren ganowa gabaɗaya tsari ne na girma sama da daidaiton sarrafawa. (3) A halin yanzu, mafi yawan abin da aka fi amfani da shi na gano kayan aikin injin CNC (a kwance m da injin milling) shine mai rikodin bugun jini na hoto, wanda ke zaɓar maɓallin bugun bugun jini na ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙwallon ƙwallon CNC na kayan aikin CNC, ƙaramin motsi na tsarin CNC, haɓakar umarni da haɓakar ganowa. ( 4) Lokacin zabar nau'in ganowa, yakamata a la'akari da cewa na'urar sarrafa lambobi tana da da'irar mu'amala mai dacewa.